If I recall correctly, the only place backpressure is important is in a 2-stroke. I know my model aircraft need a certain amount so the fuel tank can be pressurised (which obviously then forces fuel into the carburettor, allowing flight at any angle or attitude).

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3" Exhausts and low RPMs

- Thread starter ToyTruck

- Start date

Help Support Nissan Navara Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

ToyTruck

Member

Hi Tony,

Maybe instead of "loss of power" I should've said "loss of torque". By low RPMs I mean below 1,500. This is felt much more when starting up on inclines. When the exhaust was stock, I could release the brakes and not have to step on the gas (mine's an auto) and it would still stay stationary. A bit of gas (<1400 RPM) and it would climb up.

When I had the dump/exhaust fitted (without the chip) I'd have to rev it to around 1,500 to stay stationary, around 1,800 to get it going.

Maybe instead of "loss of power" I should've said "loss of torque". By low RPMs I mean below 1,500. This is felt much more when starting up on inclines. When the exhaust was stock, I could release the brakes and not have to step on the gas (mine's an auto) and it would still stay stationary. A bit of gas (<1400 RPM) and it would climb up.

When I had the dump/exhaust fitted (without the chip) I'd have to rev it to around 1,500 to stay stationary, around 1,800 to get it going.

Sounds more like the auto transmission oil was changed? That's a considerable difference for a diesel. At 1800rpm your turbocharger is approaching full boost and climbing the steepest part of the torque curve. If you have to rev it that hard to make the auto hold, I'd really look at the transmission oil.

There might be something amiss with the torque converter too but starting with the oil is a cheaper test!

There might be something amiss with the torque converter too but starting with the oil is a cheaper test!

DieselTuner2

Member

...

Last edited:

ToyTruck

Member

Sounds more like the auto transmission oil was changed? That's a considerable difference for a diesel. At 1800rpm your turbocharger is approaching full boost and climbing the steepest part of the torque curve. If you have to rev it that hard to make the auto hold, I'd really look at the transmission oil.

There might be something amiss with the torque converter too but starting with the oil is a cheaper test!

No Tony, the ATF hasn't been changed, all thats been changed was the exhaust.

Just took it recently from the stealership for its 40,000km service and noticed they hadn't changed the ATF. When I asked the service guy why as most of the automatics I've had change the ATF every 40k specially since I'm mostly in city traffic, the guy just said "We change it every 100,000kms." That's an awful long time to go between changes I think. Will changing the ATF make it better? All I know about ATF is to change it every 40k or if it smells burnt.

Just checked the ATF, still clear with no burnt smell.

Last edited:

The turbine gets is power from the velocity & pressure of the exhaust gas passing through the aperture on its inlet. That's the back end of the exhaust manifold itself - nothing to do with the dump pipe or the remainder of the exhaust beyond, which are all on the "downstream" side of the turbine - the energy has already been expended driving the turbine at that point, so I'm at a bit of a loss as to why the larger exhaust could have such a dramatic effect on your vehicle.

It might be an idea to conduct a stall test. Nissan know how to do it, the procedure for it is in the manual. Odds are that it'll fail - if your car's under warranty, maybe you should tell them it's got issues delivering power.

It might be an idea to conduct a stall test. Nissan know how to do it, the procedure for it is in the manual. Odds are that it'll fail - if your car's under warranty, maybe you should tell them it's got issues delivering power.

don't forget where talking variable turbo and ecu controlled systems.

changing the exhaust changes the way the turbo operates and then theres the effect of the ecu adjusting due to the very slight increase in flow.

one thing i have wondered about is if the 3" exhaust makes it more efficient at idle (doesn't need to be much) and the ecu adjust to maintain idle and relearns the new idle fuel requirements and trims fuel across the range.

so your loss of power is the ecu decreasing fuel rather than the exhaust making the engine worse.

just a theory that would be nice to confirm or bust.

changing the exhaust changes the way the turbo operates and then theres the effect of the ecu adjusting due to the very slight increase in flow.

one thing i have wondered about is if the 3" exhaust makes it more efficient at idle (doesn't need to be much) and the ecu adjust to maintain idle and relearns the new idle fuel requirements and trims fuel across the range.

so your loss of power is the ecu decreasing fuel rather than the exhaust making the engine worse.

just a theory that would be nice to confirm or bust.

ToyTruck

Member

@Northside

Do you have a graph comparing stock to 2.5" and 3"? My mandrel bent is catless btw. Stock Thai built Nav here has a 2.25" with cat and as far as I can tell some crush bends.

@Tony

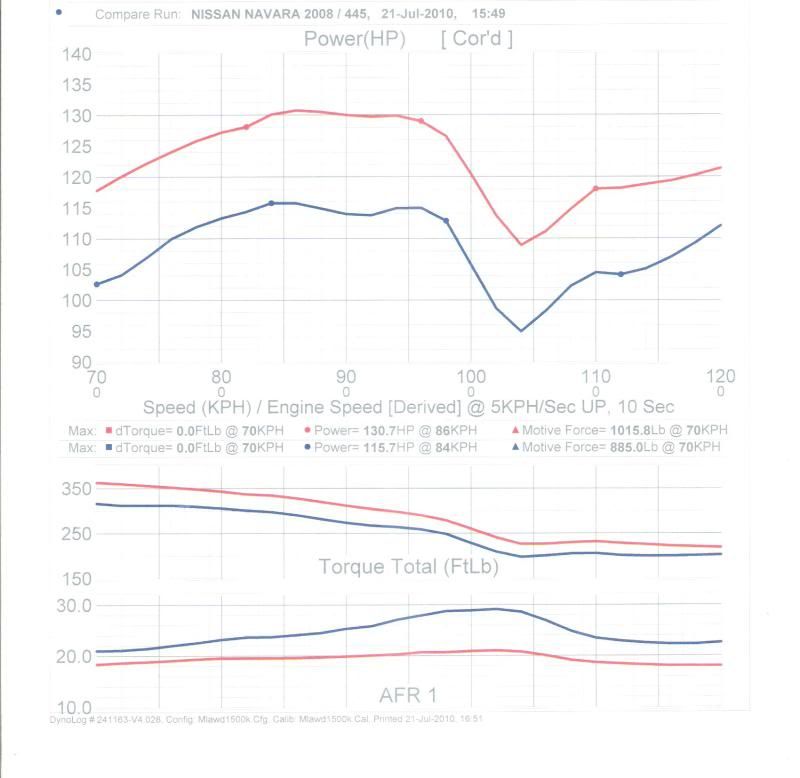

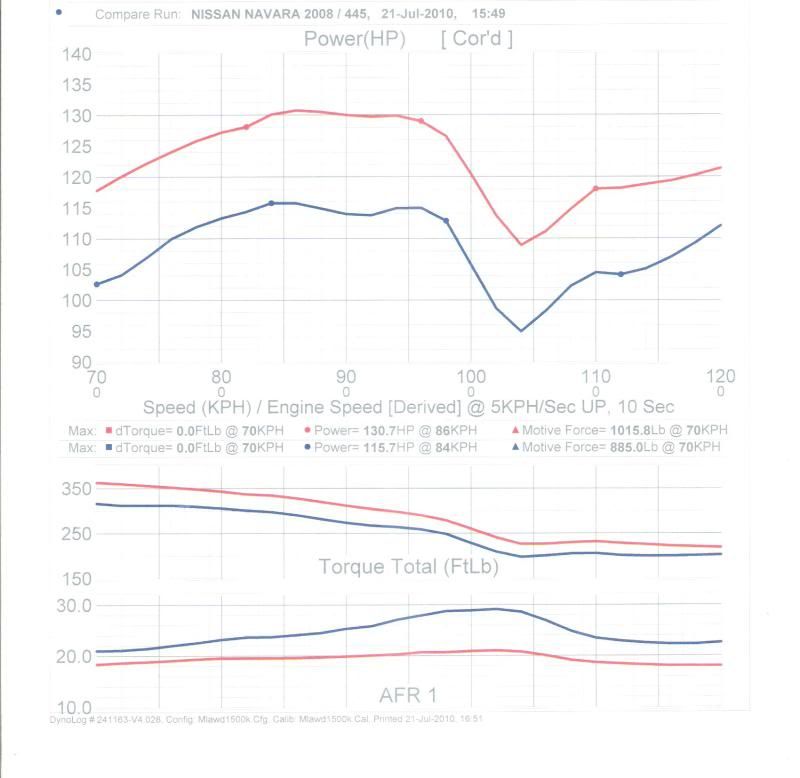

I'll probly get the stall test done. Although I'm a month past warranty. This is a dyno sheet of my truck before I got the exhaust fitted:

This is a dyno sheet of my truck before I got the exhaust fitted:

Could the dip (upshift) be a symptom of a torque converter problem? My mates have the same truck (also automatics) and they don't have that dip on their graphs.

@tweak'e

I've had another dyno run with the 3" on but the dyno won't record below 2000RPM. Couldn't get the AFR down low. So far I haven't heard of any complaints from the 126KW guys, but most of us 106KW version guys have lost some torque down low.

Thanks guys.

Do you have a graph comparing stock to 2.5" and 3"? My mandrel bent is catless btw. Stock Thai built Nav here has a 2.25" with cat and as far as I can tell some crush bends.

@Tony

I'll probly get the stall test done. Although I'm a month past warranty.

This is a dyno sheet of my truck before I got the exhaust fitted:

This is a dyno sheet of my truck before I got the exhaust fitted:

Could the dip (upshift) be a symptom of a torque converter problem? My mates have the same truck (also automatics) and they don't have that dip on their graphs.

@tweak'e

I've had another dyno run with the 3" on but the dyno won't record below 2000RPM. Couldn't get the AFR down low. So far I haven't heard of any complaints from the 126KW guys, but most of us 106KW version guys have lost some torque down low.

Thanks guys.

It's hard to say what is causing that dip. The torque converter is smack in the middle of the drive train and therefore could easily have an impact on rear wheel output.

When this dyno measurement was being taken, what was the climb in engine rpm like - was it a smooth climb all the way up, or did it have moments of higher rpm before settling down? I'm particularly wondering about where the dip occurred, which happens to be about at the point where (under a moderate load) our cars would lock their torque converters to solidly engage the driveline. Under a light load, the TCC would lock at about 80-85km/h.

When this dyno measurement was being taken, what was the climb in engine rpm like - was it a smooth climb all the way up, or did it have moments of higher rpm before settling down? I'm particularly wondering about where the dip occurred, which happens to be about at the point where (under a moderate load) our cars would lock their torque converters to solidly engage the driveline. Under a light load, the TCC would lock at about 80-85km/h.

DieselTuner2

Member

/../.

Last edited:

Chip Tuning

Member

If I recall correctly, the only place backpressure is important is in a 2-stroke. I know my model aircraft need a certain amount so the fuel tank can be pressurised (which obviously then forces fuel into the carburettor, allowing flight at any angle or attitude).

Non turbo petrol engines need back pressure as well. In the days when we used to tune petrol race engines we used to make headers with very short exhaust runners and watch the torque numbers climb and then file (yes file) the exhaust lengths shorter to see further improvements in torque. But then we would go to far and see the numbers fall away. Those exhausts we used to sell cheap (of course, this was still much better then a mass produced custom jobbie).

We would then start again and stop at the length that made the highest numbers.

This was in the days BEFORE turbo chargers and ZERO back pressure.

It was what we called "tuned" exhausts. Then the word got bastardized and everything became TUNED even when it just had a lick of paint on it

DieselTuner2

Member

...

Last edited:

DieselTuner2

Member

...

Last edited:

Tappet

Member

It would certainly drop backpressure for sure. How much, well it take a fair bit of maths to work that out to put a figure on it.Quick reminder that the question still stands.

How much does a 3" system drop backpressure over a 2.5" system?

As you say the question still stands. To my understanding I would of thought a larger exhaust would allow the turbo to spool up faster and at lower engine RPM. Infact quite the opposite situation from what the O.P. is experiancing. Perplexing.

If I think back to my rev head turbo (late 70's/early 80's) days we used to fit the biggest exhuast possible to reduce lag and even if we couldn't get the large bore around the back axle we would step it down after the muffler. The pipe off the turbo was a big thing, next was trying to stop the detonation.

ToyTruck

Member

Far from being an expert but with my limited knowledge I think the exhaust flow at low RPMs (est 1000-1300) can't spool the turbo with the bigger exhaust. To me it makes sense, exhaust velocity at those RPMs is slower since the gas has a lot of space to expand. At the higher RPMs the exhaust flow is greater so it can spin the turbine faster.

I've also read somewhere that more backpressure is good for more torque, less of it good for more power. This is what I seem to be experiencing. Loss of torque at the low end and plenty of power in the top end.

You could try to see at what RPM your engine can keep the truck from going backward at a moderately sloped incline while on the stock exhaust. After fitting the exhaust and changing nothing else try it again on the same spot. I bet you a six pack the RPM you need to be at will be a bit higher.

I've also read somewhere that more backpressure is good for more torque, less of it good for more power. This is what I seem to be experiencing. Loss of torque at the low end and plenty of power in the top end.

You could try to see at what RPM your engine can keep the truck from going backward at a moderately sloped incline while on the stock exhaust. After fitting the exhaust and changing nothing else try it again on the same spot. I bet you a six pack the RPM you need to be at will be a bit higher.

DieselTuner2

Member

...

Last edited:

DieselTuner2

Member

...

Last edited:

LLadnar

Member

Nice work northside 4x4.

Similar threads

- Replies

- 4

- Views

- 725